GROTE FRESH PRODUCE SLICER,

food grade stainless steel...

Grote FPS-1000 Fresh Produce SLICER

Grote FPS-1000 Fresh Produce SLICER

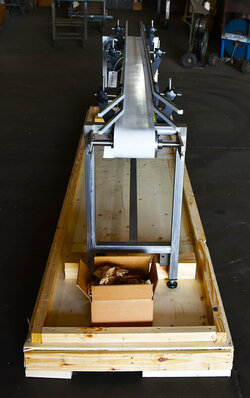

with thru-CONVEYOR, Alard item Y4786.

The Grote Model FPS-1000 "Fresh Produce Slicer" is a continuous band slicing machine, for quick and consistent bulk slicing of a wide range of produce, from delicate tomatoes to rigid onions, without damage or cracking.

FEATURES:

Manufacturer rated for up to 120 strokes per minute across a 30 inch wide slicing zone.

Manufacturer rated for up to 120 strokes per minute across a 30 inch wide slicing zone.- Crank adjustable for slicing thickness up to 1.5 inch (38.1mm).

- Designed with sloped surfaces, bead-welded seams and removable parts for ease of cleaning.

Includes a variety of infeed tube sizes to best fit your particular application:

Includes a variety of infeed tube sizes to best fit your particular application:

- Six (6) 3 inch diameter.

- Six (6) 3.5 inch diameter.

- Two (2) 4 inch diameter.

- One (1) 4.25 inch diameter.

- Sliced product drops directly onto a takeaway / discharge conveyor:

- 33 inch wide by 9.75 foot long food grade rubber conveyor belt.

- 35 inch working height with adjustable threaded rod feet.

- 33 inch wide by 9.75 foot long food grade rubber conveyor belt.

- Operator control panel with safety interlock system.

- All food grade sanitary stainless steel construction.

- 208 / 230 volt 3 phase electrical input.

As of this writing, this continuous fruit and vegetable slicer is in stock at ALARD, in EXCELLENT operational, mechanical, electrical & cosmetic condition, available for timely shipment.

CALL 315-589-4511 to confirm availability and discuss your industrial volume food cutting machine/ equipment needs.

ALARD item reference #: Y4786