VIDEO DEMO

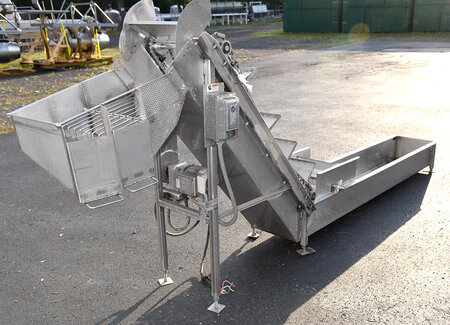

Gridpath VIBRATING DEWATERING SHAKER

/ VIBRATORY FEED CONVEYOR,

89x36, food grade stainless steel...

DEMO VIDEO

Vibrating SHAKER DEWATERING cabbage Y4520

from Alard Equipment Corporation..

A Gridpath Solutions VIBRATING SHAKER, a vibratory shaker-grader feeder for grading, size sorting, fines removal, solids separation, water reclaim / dewatering, declumping and / or even-feeding downstream components...

FEATURES:

- 36 inch wide by 89.5 inch long vibrating conveyor bed.

- 6 inch high stainless steel sides.

- 8 inch long dimpled / rigidized solid sloped infeed section.

- (2) 36 inch wide by 36 inch long stainless steel wedge-wire water reclaim / separator screens with 1/8 inch sieve openings running perpendicular to product flow.

- 9.5 inch long dimpled / rigidized solid discharge section.

- 6 inch high stainless steel sides.

- Full length water collection pan with center bottom basin tapering to a 2.5 inch diameter pipe outlet.

- 47 inch infeed height, 44.5 inch high discharge.

- Heavy duty tubular frame with rubber isolation mounts.

- Quick release clamps for easy, tool-less removal & cleaning of screens.

- Vibratory action provided by two (2) 1/3 HP rotary / eccentric vibrator motors.

- All food grade sanitary stainless steel construction.

- 208 / 230 / 460 volt 3 phase electrical input.

As of this writing, this vibratory shaker-grader is in stock at ALARD, in EXCELLENT operational, mechanical, electrical & cosmetic condition, available for immediate shipment.

CALL 315-589-4511 to confirm availability and discuss your food handling needs.

ALARD item reference #: Y4520